Tempering Process

- It includes heating and cooling stages in order to give permanent compressive stress on outer surfaces of glass on horizontal line and an indirect tensile stress to the middle of glass.

- It increases mechanical strength and thermal shock resistance of glass. It does not change the volume, chemical structure, color and clarity of products.

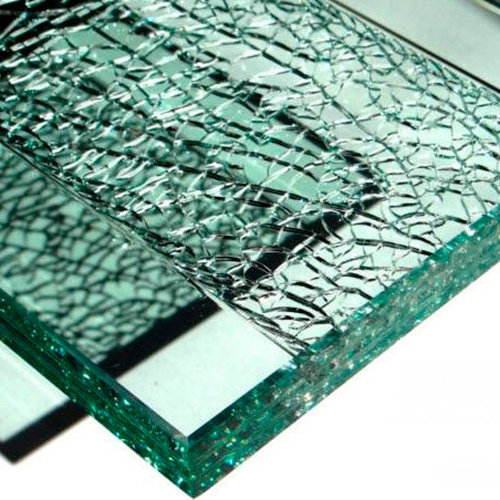

- Tempered Glass is about five times more resistant to impacts comparing to sheet glass without the application of thermal process. Since it decreases the risk of injury by falling to small and blunt pieces when it is broken, it is suitable to be used as safety glass.

- It includes heating and cooling stages in order to give permanent compressive stress on outer surfaces of glass on horizontal line and an indirect tensile stress to the middle of glass.

- It increases mechanical strength and thermal shock resistance of glass. It does not change the volume, chemical structure, color and clarity of products.

- Tempered Glass is about five times more resistant to impacts comparing to sheet glass without the application of thermal process. Since it decreases the risk of injury by falling to small and blunt pieces when it is broken, it is suitable to be used as safety glass.

In our factory

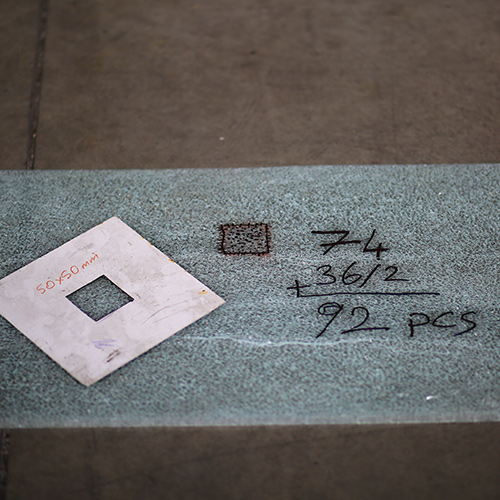

- Processable Glass Properties: 4 mm – 19 mm

- Min.size: 200×400 mm – Max.size: 2400×4200 mm

- Flat Temper Capacity: 600,000 m2/year

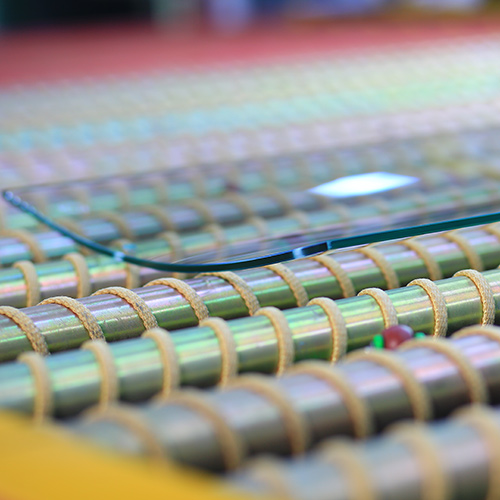

Tempering process is completed with shaping the glass which is heated in tempering furnace up to a specified temperature just as sheet glass by transfering it to tempering and cooling section which is adjusted according to the requested bending angle.

In our factory

-

Processable Glass Properties; 3,5 mm-12 mm

-

Min. size:350×350 mm – Max. size:1000×2400 mm

-

Curved Tempered Capacit

y: 100,000 m2/year

English

English Türkçe

Türkçe